As an industrial company, Vossloh is committed to minimizing negative environmental impact along the entire value chain. The goal: climate neutrality by 2030 (Scope 1 and 2) – with a clear reduction path and measurable progress each year.

The entire Vossloh team is continuously working to make products more resource-efficient, reduce energy consumption, and embed circular economy principles in development, production, and maintenance. In doing so, the company relies on environmentally certified management systems, fact-based decisions, and innovations that reduce the rail sector's ecological footprint in the long term.

Climate target

Vossloh aims to achieve carbon neutrality in its own business operations (Scope 1 and 2) by 2030. This goal was incorporated into Vossloh's sustainability strategy at an early stage in order to mitigate and adapt to physical and transitory risks associated with climate change. This target also enabled Vossloh to keep pace with developments among customers, markets, and environmental requirements. The necessary reduction in CO2e intensity of 11 percent per year is backed by concrete measures and CO2e budgets. Remaining – locked-in – emissions must then be compensated. Vossloh is also currently working on solutions to reduce indirect (Scope 3) emissions measured for the first time in 2024, which are largely beyond its direct control.

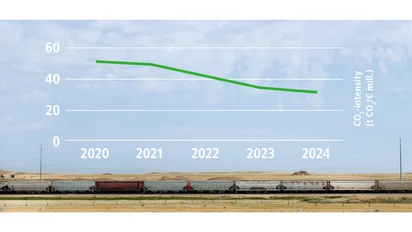

On the path towards 2030, Vossloh has already succeeded in decoupling its economic growth in the past years from CO₂ emissions. This is evident from a glance at CO₂ intensity. CO₂ intensity per million euros of sales indicates how many tons of carbon dioxide (CO₂) a company emits on average to generate one million euros in sales. This indicator compares the emissions caused with economic performance and thus serves as a measure of climate performance per unit of sales.

Although this target is not formally scientifically based, the company sees its goal of climate neutrality for its own business activities as a contribution to supporting the goals of the Paris Agreement. The agreement calls for limiting global temperature rise to well below 2 degrees Celsius, ideally to 1.5 degrees, and requires greenhouse gas neutrality in the second half of the century. The planned climate neutrality in its own business operations (Scope 1 and 2) by 2030 is within this time frame and contributes to reducing the risks of climate change.

Vosloh primarily uses the Greenhouse Gas Protocol (GHGP) and the international standard for energy management systems ISO 50001 to measure, report, and control emissions, including setting targets. The climate neutrality target for 2030 (Scope 1 and 2) is based on assumptions regarding sales development that are guided by Vossloh's rolling three-year planning and longer-term linear sales growth. To achieve its climate neutrality target, Vossloh has been intensifying its measures to decarbonize the Group since 2021.

Transition plan until 2030

The transition plan for climate protection developed in 2024 relates to Scope 1 and 2. It identifies four decarbonization levers across the Group: use of renewable energies, electrification, switch to less CO2e-intensive fuels, and improvement of energy efficiency. The company currently estimates that in 2030, the amount of greenhouse gas emissions that cannot be eliminated (locked-in emissions) will be 11,000 tons of CO2e. Those remaining CO₂e emissions will be offset annually. At the same time, new technologies are continuously evaluated with the aim of reducing bound emissions. The long-term goal is to replace offsetting with actual emission reductions to sustainably lower the environmental footprint. The transition plan until 2030, based on the base year 2022, can be seen on the right.

The expansion of emissions reporting to include the upstream and downstream value chain in fiscal year 2024 is a first step toward contributing to climate protection beyond the defined target in the future.

Measures and initiatives against climate change

The use of renewable energies, primarily through the purchase of green electricity and on-site photovoltaic systems, offers by far the greatest potential for CO2e savings. Seventy-five percent of the electricity purchased for all units worldwide comes from renewable energy sources. In addition, around a quarter of Vossloh's sites are equipped with their own solar power systems. Solar parks have been installed in India, Poland, China, Mexico, The Netherlands, and Germany. In the Rail Services business unit and, to a lesser extent, in the Tie Technologies business unit, a change in the fuel used is also taking place. At Vossloh Rail Services, this involves the use of hydrogenated vegetable oils (HVO) instead of diesel for the engines of trains and machines used in maintenance services.

In all four business units, Vossloh is conducting life cycle assessments (LCA) on an increasing number of products and services in compliance with ISO standards. To minimize the negative environmental impact of the company’s solutions, the findings are integrated into the innovation and development process for products and services which follows eco-design principles. Since December 2023, a group-wide guideline for the ecological design of products and services (EcoDesign Guideline) has supplemented the innovation policy. The guideline focuses on the design and construction phase, as these have the greatest impact on a product's ecological footprint. Life cycle analyses carried out since then have shown that the following ecological design principles have the greatest impact on the ecological footprint of Vossloh's portfolio: use of renewable and/or recycled materials, efficient use of materials, energy efficiency, and efficient logistics/packaging. The development departments therefore pay particular attention to these four principles.

Circular economy

Vossloh's core products, such as rail fastening and switch systems or concrete sleepers, generally have a long service life – a characteristic feature of rail infrastructure. Once installed, they remain in the track for years or decades and are largely maintenance-free during their service life. At the end of their service life, the products are also almost completely recyclable. Points and crossings, for example, can remain in service for around 30 years, depending on the load and maintenance, while rail fastening systems can last for around 40 years. Concrete and composite sleepers can be expected to have a service life of 40 to 50 years. Vossloh's services, such as rail grinding and milling or monitoring services, help to ensure that existing rail infrastructure can be used for longer.

Raw materials are needed to manufacture the products, such as steel and plastic for rail fastenings and switches, or concrete for sleepers. Grinding stones are used for rail maintenance. Vossloh tries to go without packaging wherever possible. If absolutely necessary, packaging is designed to be ideally 100% reusable, by switching to increasingly recyclable products, and by increasing the overall recycling rate. For a new switch point, a circular economy model was developed in collaboration with customers for the first time, enabling old manganese crossings to be reused. Recycling the material not only reduces CO2e emissions but also mitigates the environmental, health, and social impacts associated with manganese extraction, thereby meeting Vossloh's sustainability goals.

Vossloh's products currently consist of over 97% recyclable materials. For future product lines, this feature will be an integral part of the development requirements from the outset.

Environmental management systems

Environmental and climate protection are an integral part of Vossloh's operational processes. Environmental officers have been appointed at the locations of the Group companies and appropriate reporting systems have been installed. As of December 31, 2024, 79% of employees were employed at an ISO 14001 (environmental management) certified unit. The proportion of operating companies with corresponding certification was 64%. Energy management systems in accordance with ISO 50001 are also in place.