FLEXIBLE. CUSHIONING. RELIABLE.

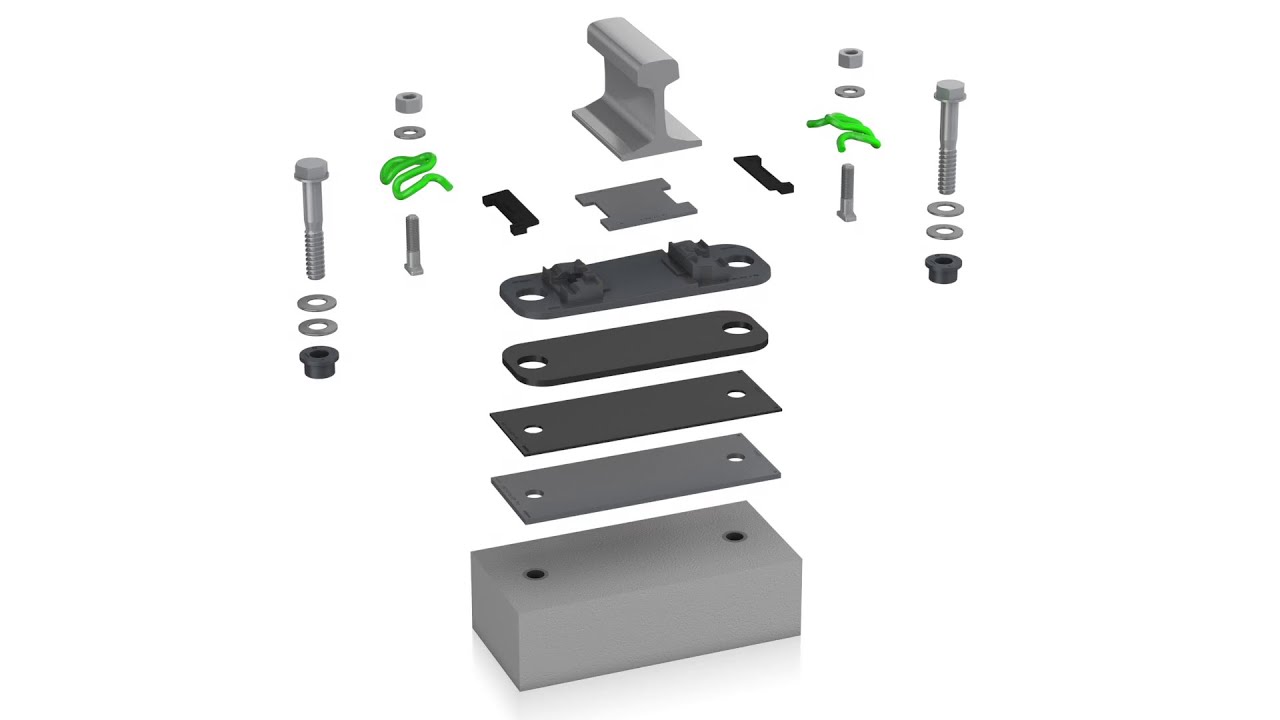

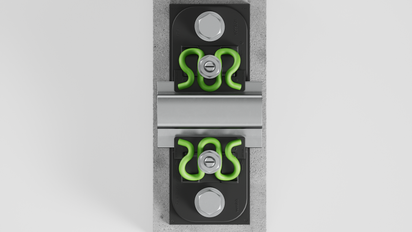

Slab track poses its own challenges, especially in urban local transportation. It is not a question here of extreme speeds but of tight schedules, repeated starting and braking and limited space that place demands on infrastructure. The 200 MFlex meets these challenges with a carefully considered combination of elasticity, stability, and intelligent damping behavior.

By virtue of its modular design, in combination with our innovative M7, the system can be adapted precisely to these specific applications – whether in metro, for trams or in turnout areas. In symmetrical or asymmetrical designs, the system adapts flexibly to different structural conditions.

.jpg?format=webp&quality=85&crop=2409,2409,x0,y602&width=60)