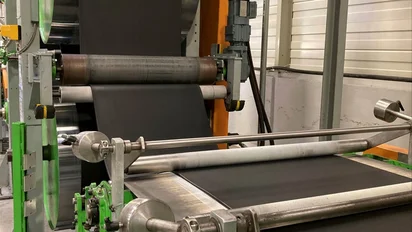

Modern rail fastening systems offer the necessary elasticity to ensure that forces caused by track and wheel irregularities do not lead to excessive wear or damage that causes vibrations and structure-borne noise. cellentic plays a key role in dampening these vibrations in the form of highly elastic intermediate layers or intermediate plates; the elastomers are individually cut to size for turnouts.

This unique elastomer made from EPDM (ethylene propylene diene monomer) retains its original shape even under repeated stress thanks to its closed-cell structure.

Additional features and benefits:

- resistant to chemical influences

- UV resistant

- outstanding temperature, aging, and weather resistance

- excellent resistance under continuous stress; no plastic deformation

- high damping of shock loads

- Pre-assembly capability thanks to pre-assembly lips

fin design for even greater flexibility and safety during track installation

Vossloh's latest interlayer made of cellentic features an innovative design. While the proven H-shape ensures that the intermediate layer is correctly positioned under the rail and between the angle guide plates, the additional fin design provides significantly improved flexibility during track installation in the event of significant longitudinal rail displacement due to high temperature fluctuations.

Vossloh offers a suitable fastening system for every type of rail installation. Its highly elastic intermediate layers made of cellentic take on the elasticity of the ballast superstructure.

Optimal protection for the superstructure – on all types of tracks

Minimizing vibrations and structure-borne noise is not only important for local transportation. Vossloh's rail fastening systems with highly elastic cellentic interlayers are also used in conventional long-distance and high-speed rail transportion. Excessive loads can cause the ballast substructure to become overloaded if there is insufficient load distribution across the intermediate layer.

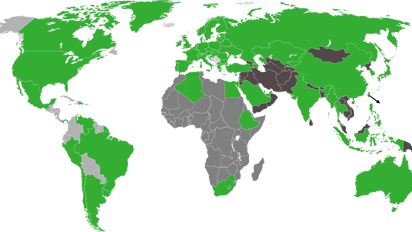

Global application

Reference examples for intermediate layer 104 NT with a stiffness of 22.5 kN/mm:

- "Olympic route" between Beijing and Tianjin

- High-speed rail lines

- Cologne–Frankfurt (built in 2001/02)

- Nuremberg–Ingolstadt (2004/05)

- Hanover–Berlin (2010)

- in the Katzenberg Tunnel and

- between Gröbers and Erfurt (2011/12)

Downloads

()

- EN

- DE

- FR

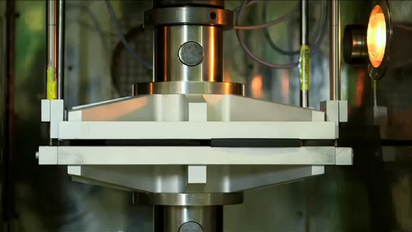

Sustainable manufacturing process without nitrosamines

cellentic 2.0 is the next-generation compound for EPDM intermediate layers and pads, formulated with alternative vulcanization accelerators. This prevents the emission of nitrosamines – a trace gas that is ubiquitous in the environment and is mainly released into the atmosphere during vulcanization and tempering:

- Healthier working conditions for employees,

- improved exhaust emissions in production,

- The environment and superstructure are now protected in an even more environmentally friendly way.

Compared to the previous manufacturing process, we are reducing CO₂ emissions by 12% with cellentic 2.0. These savings apply to the entire life cycle.

The comprehensive product portfolio covers all areas of application. The elastomers can be produced in series or as customized individual solutions. In addition to project-specific dimensions, the cut sections are precisely tailored to the turnout geometry.