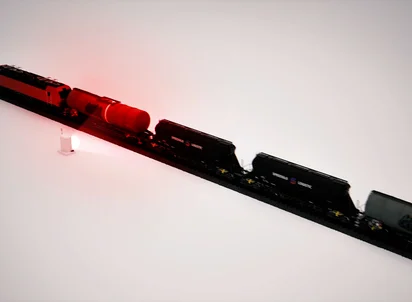

Wagon identification and condition monitoring Problem description

Harbors, terminals, and chemical parks often lack precise train data upon arrival, relying on inaccurate wagon lists. This leads to issues with wagon sequence, load position, and liability for damages.

Our solution uses various sensors, such as cameras and microphones, to cap-ture and analyze train data and provide accurate information within minutes.

This helps optimize operations, prevent disruptions, reduce liability risks, and enhance safety and productivity.