Regulations require that rails are regularly inspected in order to prove that they are in good condition. Vossloh's modular service offering enables customized solutions for all tasks.

You determine the right mix of service and in-house work that will deliver optimal results: from consulting and planning to start up assistance for the internal development of maintenance work and services to a comprehensive, worry-free package.

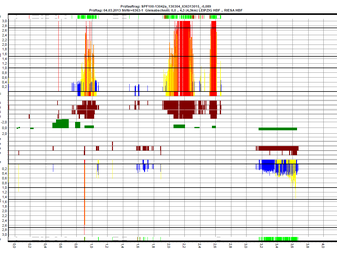

Choosing the right rail and turnout processing method requires detailed knowledge of the current condition of the rails. Some damage can certainly be detected by a professional with the naked eye. But what about the material fatigue that is invisible beneath the rail surface? You cannot rely on experience alone here. Due to varying axle loads and train densities, rolling contact leads to hardening, crack formation, and – if preventative measures are not taken – to significant rail and turnout damage at very different rates across network segments. Regular measurements and inspections of the track system are therefore essential in order to determine the optimal maintenance time in each case.

.jpg?format=webp&quality=85&crop=956.4,956,x372.1,y229.9&width=60)