The road-rail milling truck perfectly complements the fleet of mobile milling machines. Thanks to its roadworthiness, it is extremely versatile and therefore offers maximum mobility, easy loading and unloading, and very short set-up times. In addition to the convertible track width (1,000–1,520 mm), its milling capabilities include the machining of:

Milling technology for machining grooved rails

Up until now it hasn’t been possible to correctively machine grooved rails without removing the sealing compound that runs virtually flush along the rail’s outside edge. The special tool on our road-rail milling truck has a wheel flange equipped with cutting tips. With this tool it is now possible to rectify defects in a single pass without great expenditure and with deeper radius machining. A positive-tangent cutting angle starting at Y+0 also enables us to achieve a cutting zone that extends to Z-22 mm on the rail’s running edge. With larger removal rates, this prevents the wheel flanges on the trams’ wheels from bottoming out in the rail groove.

()

- EN

- DE

- FR

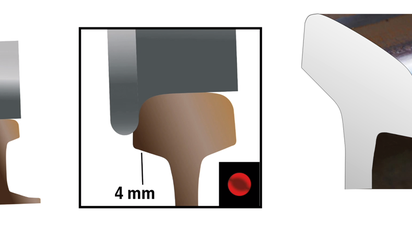

Milling side wear on curved track

Over time, the centrifugal forces that occur when trains travel through curves produce a negative copy of the wheel profile in the gauge corner of the curve’s inside rail. Wear marks begin to form in the early stages and in later stages become gouges in the side of the rail. Here the critical zone in the Y-axis starts at the 4-millimeter mark. With conventional milling tools, there’s the risk that the wheel flange will hit the bottom edge of the side gouging and consequently not remove enough material to rectify the defect. After it has been machined with the SF02 milling truck, which is configured for rectifying specifically this type of rail defect, the rail can be machined again normally in compliance with regulations without any restrictions.

Milling technology for machining level crossings

The milling tool on the SF02 road-rail truck has the same dimensions as a rail wheel, which allows it to continuously machine rails through a level crossing – provided that the clearance at the gauge corner complies with the “European standard for wheel flanges“: 38 mm in track gauge and 42 mm in depth. The rail’s groove must also be completely free of any residue and there must be sufficient clearance to any adjacent material on the rail’s field side to allow the application of the required rail-head curvature. Ideally, this adjacent material should be 2 mm lower than the top of the rail.

()

- EN

- DE

- FR

Track gauge correction

Various circumstances can cause the track gauge to narrow in places, which inevitably leads to the track having to be closed to all traffic once its gauge falls below 1,430 mm. Proper track gauge correction using Vossloh machines corrects track gauges by 2.5 mm per rail – 5 mm in total – and quickly ensures safe, long-term operation.

Proven. Adaptable. Precise.

The SF02 W-FS completes the entire profile coverage – depending on the condition of the rails and the depth of the defects – in just one pass. The integrated grinding technology ensures fine grinding and thus further contributes to extending the service life of the rails. Thanks to minimal dust and spark generation, the risk of fire in embankment and vegetation areas is virtually eliminated.

Additional product features:

- Removal of 0.3-0.9 mm per pass

- Track correction up to 5 mm per pass

- All common rail profiles possible

- Dedicated processing of weld joints and level crossings

- No removal of track signaling components necessary

Range of services

- Mainline and turnout servicing

- New layer processing

- Preventive maintenance and servicing

- Elimination of rail head defects in the transverse and longitudinal profile

- Improved smoothness and reduced wear

- Noise reduction in sensitive areas

- Track correction

- Rail profile change

Benefits

- Transport truck and machine in one

- Transfer runs via road and rail

- Easy loading and unloading

- High flexibility

- Maximum mobility

- No removal of track signaling devices necessary

- Short setup times

- Gauge change possible at any time

Selection of reference projects

Amsterdam, Netherlands:

track correction in tunnel areas

Bergen, Norway:

Rail re-profiling in Bergen's tram network on tight curves and gradients of up to 60 ‰

Zittau, Germany:

New rail processing in a trio! Optimal use of closure periods with the road-rail milling truck in combination with Flexis System and VTM-compact.

Tilburg, Netherlands:

Rail and turnout processing of slip zones in combination with the Flexis System

Reblaus Express in Austria

The rails used by the "Reblaus Express" in Austria showed a number of rail defects. To ensure smooth processing, the gaps in the fish-plated expansion joint track were temporarily bridged. Following several demand-oriented passes, the rail was restored to its required crown profile, ensuring optimal wheel-to-rail contact."

- Denmark

- Germany

- Finland

- France

- United Kingdom

- Italy

- Croatia

- Luxembourg

- The Netherlands

- Norway

- Poland

- Sweden

- Switzerland

- Slovakia

- Czechia

- Turkey

- Hungary

.jpg?format=webp&quality=85&crop=956.4,956,x372.1,y229.9&width=60)