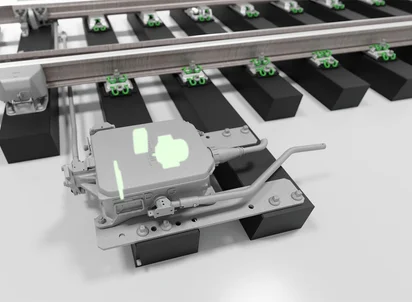

Adaptive monitoring and diagnostics catalyst Problem description

Railway operators often face unexpected point machine failures that lead to costly downtime and unplanned repairs. Without early insights into abnormal states, maintenance teams must react after the failure has already happened. This means they may not have the right tools or parts available and cannot prepare effectively. As a result, repairs take longer, costs rise, and the reliability of rail operations suffers.