Reactive and time-based maintenance Problem description

We see the need to shift from a reactive and time-based maintenance to predictive and condition-based maintenance for a more efficient maintenance but also to optimize asset lifespan.

Vossloh connect

We see the need to shift from a reactive and time-based maintenance to predictive and condition-based maintenance for a more efficient maintenance but also to optimize asset lifespan.

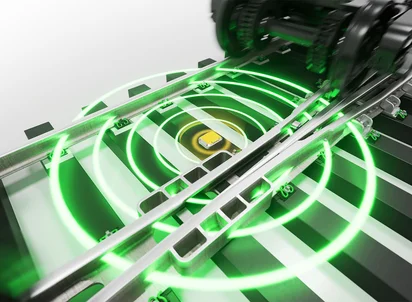

Our solution is an IoT device monitoring vibration at the level of the crossing’s nose. It enables the detection of impacts from wheelsets on the infrastructure.

Our solution allows to identify which turnouts behave abnormally at a glance by providing a dashboard with above threshold behavior. It allows as well to anticipate evolution of degradation and plan maintenance.

By checking the return to nominal condition, you can confirm the maintenance job effectiveness.

Overall, our solution enables better planning of maintenance activities by adjusting the execution of track jobs.

Our solution is composed of 2 wireless devices, to avoid complex installation and risks of failure due to damaged cable.

One sensorbox is fixed to the bearer monitoring vibration at a high frequency. The battery-powered device is transmitting data packets to the gateway with a Bluetooth low energy protocol. The transfer of data is done periodically or more frequently depending on the desired balance between battery life and response time (to be defined according to the customer need).

The gateway is also battery powered and transmits information to the cloud to ensure analysis.

All data transfers are encrypted to ensure safe operations and decrypted only in the cloud.