The importance of proper ballast tamping in turnouts Problem description

Proper ballast tamping in turnouts is vital for safe, efficient operations. Inadequate tamping can cause dips, humps, and misalignments – affecting train stability and detected by measurement trains.

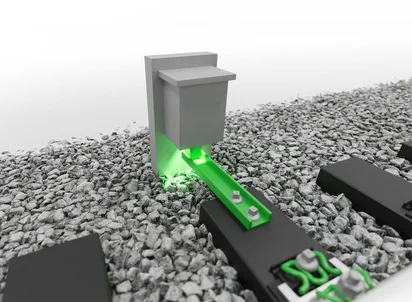

Beyond visible issues, poorly compacted ballast increases dynamic forces on turnout components – especially point machines – causing hidden vibrations that accelerate wear and raise maintenance needs.

Over time, this leads to higher costs and downtime. Consistent, high-quality tamping stabilizes the track, reduces damage, and extends asset life, improving overall network reliability.