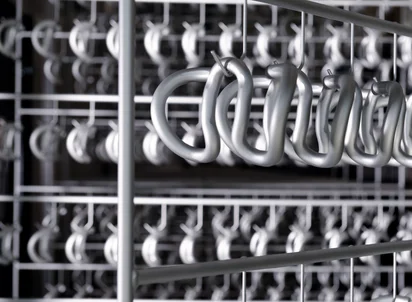

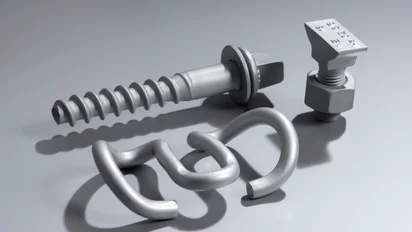

Vossloh protect: Sustainable Coating Solutions for Critical Rail Applications

Corrosion is one of the invisible yet costly adversaries of rail infrastructure. Whether in tunnels, on the coast, in industrial areas, or under extreme temperature conditions – wherever steel components are exposed to aggressive environmental influences, risks arise for safety, availability, and cost-effectiveness. This is precisely where Vossloh protect comes in: The innovative coating system offers long-lasting protection for high-strength steel components against corrosion – even under heavy chemical stress and mechanical load.

This addresses the central challenges of modern mobility: longer lifecycles, reduced maintenance costs, and greater resilience under real-world extreme conditions.