What does milling achieve?

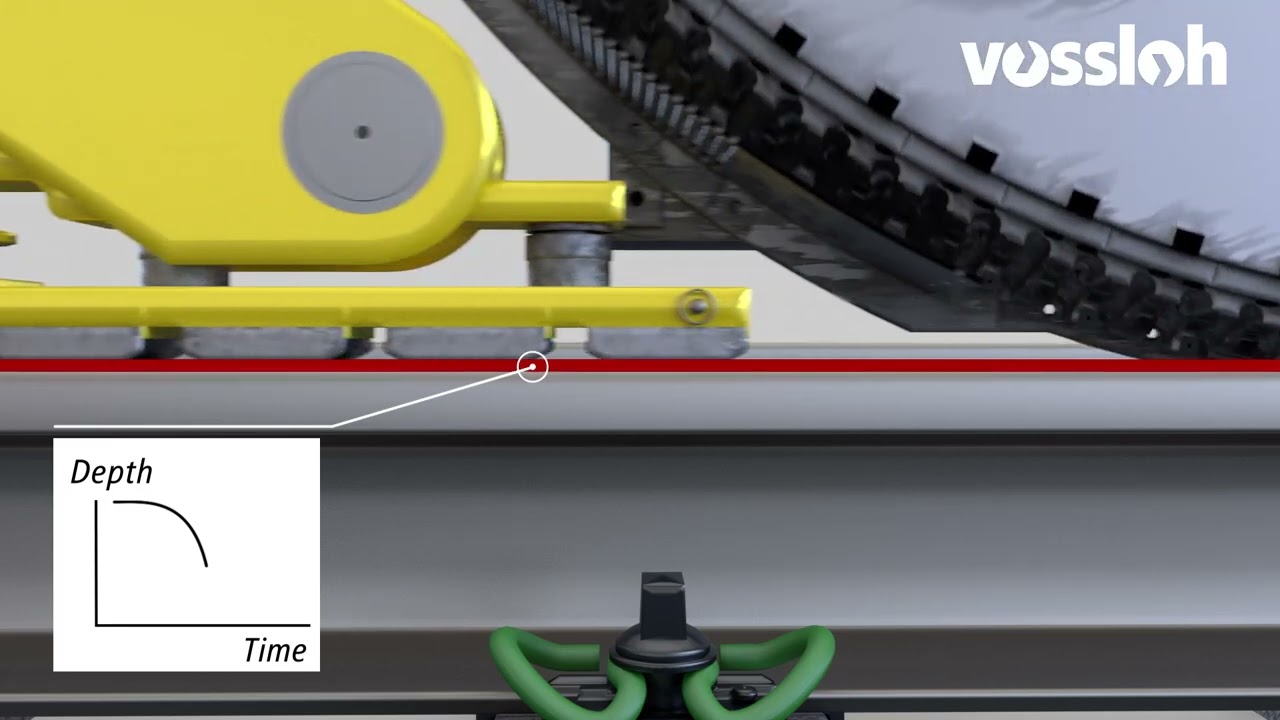

Unlike rail grinding, milling is a chip-removal process. Numerous cutting tools are mounted on a rotating milling wheel, which is guided longitudinally along the rail. The design and configuration of the milling tool vary depending on the requested operation and the required rail profile. During the milling process, which is controlled to within a tenth of a millimeter, high removal rates can be achieved per pass; depending on the machine, these range from 0.3 mm (the minimum removal rate due to the technology) to 2.0 mm on the rail surface and a maximum of 2.5 mm per running edge in one pass. This means that the optimum track gauge can be restored after wear-induced changes to the track gauge by means of gauge correction milling. On the other hand, the milling plates are arranged to match the target profile of the rail head, ensuring a continuous transverse profile.

.jpg?format=webp&quality=85&crop=956.4,956,x372.1,y229.9&width=60)